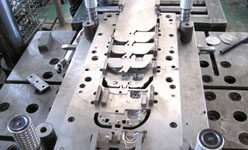

Die Stamping

We offer die stamping for all your needs

Die casting is a high pressure metal manufacturing process that forces molten metal into a mold (aka tool or tooling) cavity. The mold cavity consists of two hardened tool steel dies. A hot- or cold-chamber machine is used based on the cast metal.

We offer die casting services in a variety of materials that produce accurate and complex shapes. Die casting can produce a broad range of parts with perfect finish and astonishing detail. Our dies produce products with higher tolerance for heat and pressure, that are more durable and last longer than parts made by other methods, and are competitively priced.

We offer die casting services in a variety of materials that produce accurate and complex shapes. Die casting can produce a broad range of parts with perfect finish and astonishing detail. Our dies produce products with higher tolerance for heat and pressure, that are more durable and last longer than parts made by other methods, and are competitively priced.

For metal dies, our main expertise is in producing progressive die, drawing die and compound die. Higrade USA works with you the OEM customer to optimize stamped metal part configuration for “Best Cost” solution! For the metal dies, our main expertise in producing progressive die, drawing die and compound die.

We are more than happy to give advice on which solution is most suitable for your needs, depending on your Die needs. Please give us a call and we can go over your requirements. Our advice is free!