Specialized in Producing Injection Molded Products since 2003

Our controlled environment production molding floor has central material drying and distribution. All molding equipment has gone through an extensive installation qualification protocol and are calibrated on a regular basis. Procedures and protocols are in place to ensure the quality of each and every lot. Precise moisture analysis of raw resin is monitored throughout the part run, confirming manufacturer’s specifications have been met. All staff are trained in proper cGMP techniques. We also utilize a robust IQMS ERP system, providing real-time press monitoring and inventory control. Higrade USA Plastics offers press sizes ranging from 35 to 750 tons.

We are capable of producing and testing all sizes of injection molds. Higrade USA is a supplier of thermoplastic injection molding services including engineering and design, custom injection molding, final product assembly, mold making, and prototype development. We have many customers who come to us to manufacture a wide range of products in the medical, electronics, irrigation, and other technical industries.

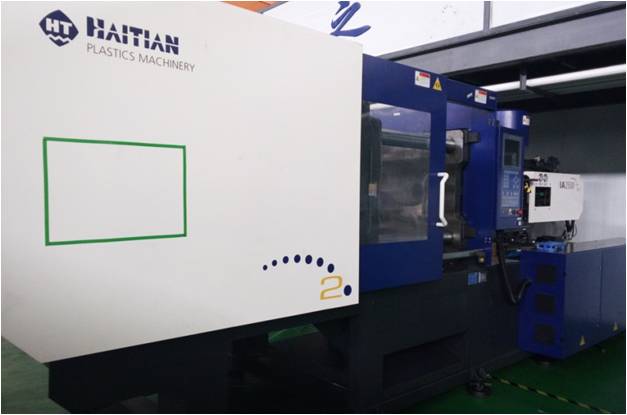

Some of our equipment

86-160T - 180T - 250T - 380T - 520T - 750T - 1300T - One Vertical Injection Machine

2-Shot

Multi-Functional Solutions – Produce products that provide dual functionality such as multi-colored, structural substrate with soft-touch features, components that require gasket or sealing type features, etc.

Improved Quality – Using the ‘single tool concept’, part variation is greatly minimized and controlled, creating a high level of repeatability. This removes the potential risk of contamination that exists using a typical two-tool over-molding process.

Cost Reductions – The entire substrate and over-mold process is accomplished in a single and simultaneous injection molding cycle requiring only ‘one’ tool. A typical alternative to true two-shot molding is an over-mold process that requires additional tooling (one tool and molding process to create the substrate, and another tool and process to complete the over-mold), as well as additional handling and labor. Two-shot can also be used to achieve a high quality multi-color product in lieu of a painting process (which can rub off).

Improved Bonding – By joining two compatible materials in a single molding cycle, a very strong bond is created without the use of adhesives between the two parts. This process yields a far more robust bonding process then using a over-mold process involving two separate tools and molding operations.

Multi-Functional Solutions – Produce products that provide dual functionality such as multi-colored, structural substrate with soft-touch features, components that require gasket or sealing type features, etc.

Improved Quality – Using the ‘single tool concept’, part variation is greatly minimized and controlled, creating a high level of repeatability. This removes the potential risk of contamination that exists using a typical two-tool over-molding process.

Cost Reductions – The entire substrate and over-mold process is accomplished in a single and simultaneous injection molding cycle requiring only ‘one’ tool. A typical alternative to true two-shot molding is an over-mold process that requires additional tooling (one tool and molding process to create the substrate, and another tool and process to complete the over-mold), as well as additional handling and labor. Two-shot can also be used to achieve a high quality multi-color product in lieu of a painting process (which can rub off).

Improved Bonding – By joining two compatible materials in a single molding cycle, a very strong bond is created without the use of adhesives between the two parts. This process yields a far more robust bonding process then using a over-mold process involving two separate tools and molding operations.

Request a Quotation - [email protected]

We are more than happy to give advice on which solution is most suitable for your needs, depending on your Injection needs. Call us now to discuss your project. Our advice is free!